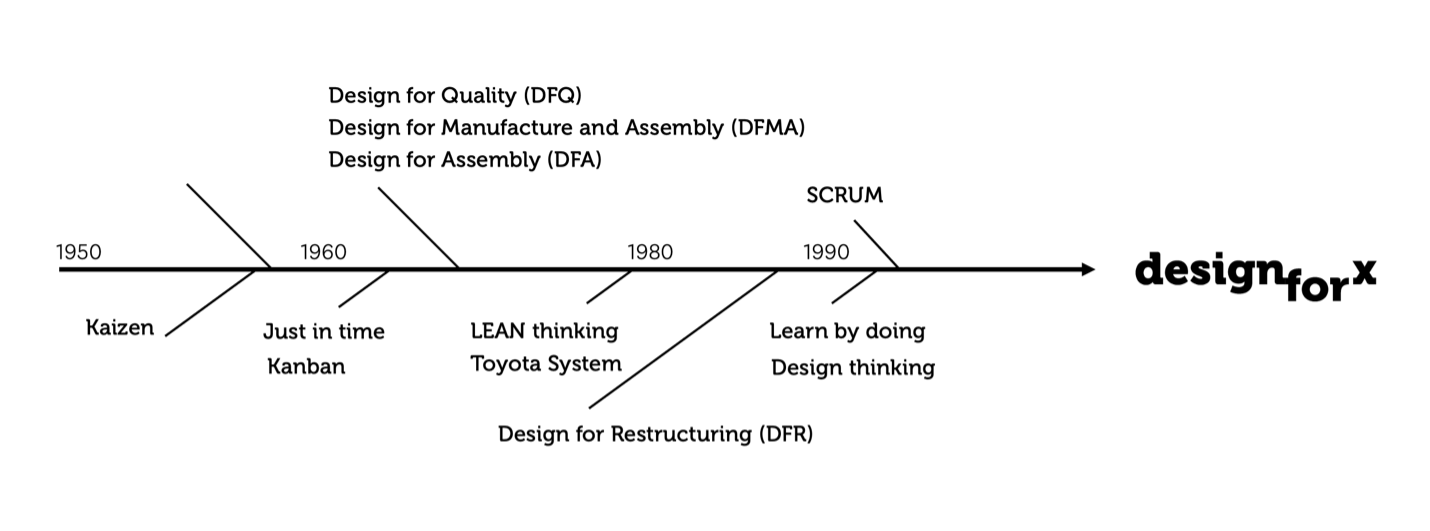

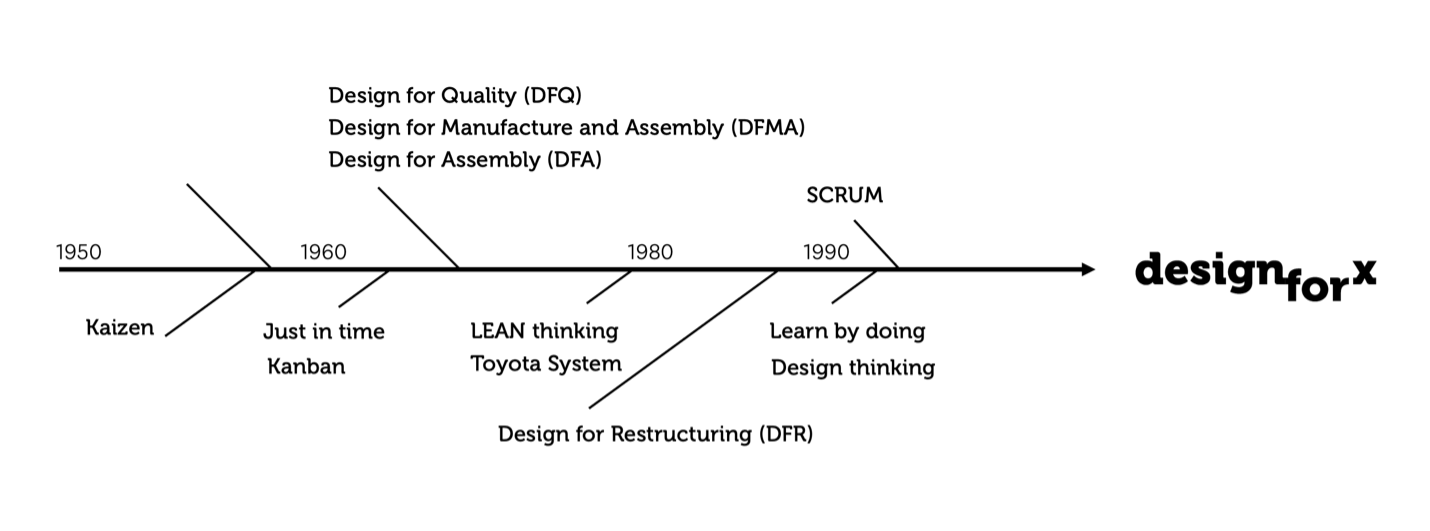

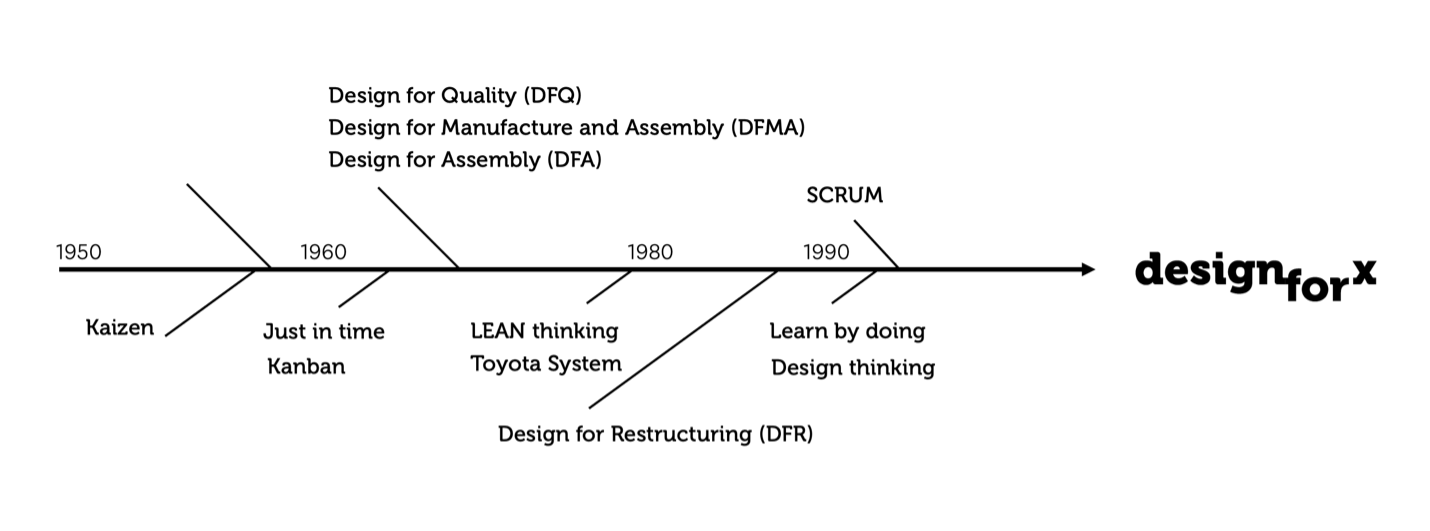

In the 70's the logic of just in time spreads with more force, which further drives the idea of

assembly linked to standardization and zero error, definitively transforming the industry and, consequently, the logic of production, logistics and marketing of products, reaching its apex in

the 90s and early 2000s.

More recently the concept of PDCA, or continuous improvement, which later evolves into the

idea of Always in Beta, has also been transported to the business world, since differentiation by

the speed of time to market has become more and more relevant with the emergence of tech

companies and start-ups. The models and reasoning that had been used to organize industries for

the administration and management of businesses and brands were transported, bringing

concepts such as Lean, Kaizen, and Kanban, among others, into organizations, resignified

through agile methods such as Learn by Doing, Lean Thinking, Scrum, Design Sprint, and

Design Thinking, which were also disseminated by business schools.

All of these variations have the same basis and the same origin, although they propose small

differences in approach that may be more interesting for one or the other strategy. This point

further reinforces the concept of Design for X, because at heart, many of these approaches, called

methodologies, are actually frameworks. Thus, Design for X is defined as a broad and flexible

methodology, which provides a greater focus on choosing the appropriate tools in the face of

project assumptions and objectives. If Design Thinking, or Design for Thinking, is a tool, Design

for X would be the toolbox.